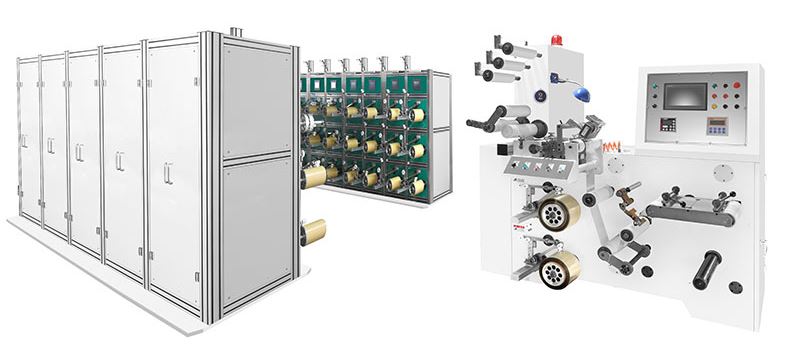

Slitting and spooling machine (Tearing Tape Slitter), LSJ60

LSJ60 slitting and traverse winding machine is mainly used to rewind 50000 meters of cigarette package tear tape. It features with high automation, high production efficiency, high product precision, etc. This machine is produced following domestic and abroad advanced technologies. It belongs to the specialized equipment of outstanding tear tape products.

Specification

| Material | BOPP, PET, OPE, PVC and other reel materials |

| Material thickness | 0.025~0.05mm |

| Material diameter | Diameter: 600mm, 3 inches paper tube |

| Guide wheel width | 300mm |

| Slitting width | 1.6mm, 2mm, 2.5mm, 3mm |

| Speed | 150m/min~300m/min |

| Precision | ≤±0.10mm |

| Rewinding number | 60 rewinding heads (optional) |

| Rewinding diameter | Max.diameter: 300mm and 6 inches paper tube |

| Rewinding width | Maximum 185mm |

| Total power | 66kw |

| Supply voltage | 380V 3P 50Hz |