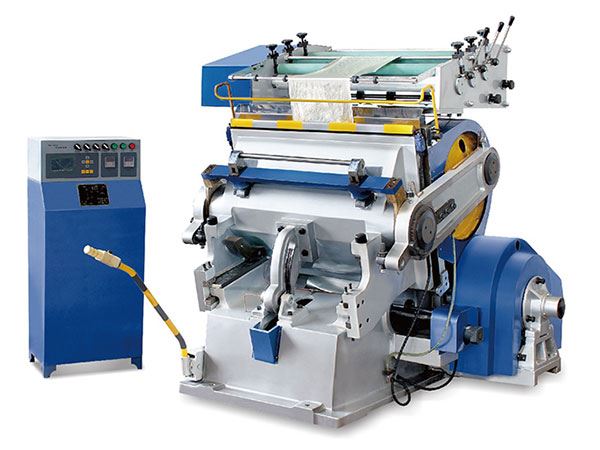

Manual Fed Hot Stamping and Die Cutting Machine

This machine is suitable for thermo printing hot-stamp foil onto various paper products, and also can be used as cutting machine for mold cutting and creasing various cardboard boxes and cases. Various high-grade exquisite printed products can be thermo-printed concavely and convexly on this machine so as to get stereoscopic, exquisite and beautiful packed and decorated products.

Features

- It is controlled by single-chip microprocessor

- Foil-feeding rubber roller of electrochemical aluminum is driven by stepper motor

- The user can use two or threes sets of stepper motor at the same time

- The length and leapfrog parameters of electrochemical aluminum foil-feeding can be set according to different size of stamping foil

- This kind of converting machine is simple to use and convenient to maintain

Application

- This machine is a kind of packaging converting machinery used for thermal printing and creasing various products, such as cardboard, leather and plastic etc.

- It is suitable for thermal printing various paper products with electrochemical aluminum

- It also can be used for die cutting and creasing cardboard cases and boxes

Specification

| Model | TYMQ1100 |

TYMQ930 |

TYMQ750 |

| Plan metric effective area | 1100×800 | 930×670 | 750×500 |

| Total electro thermal power | 9(kw) | 9(kw) | 4.5(kw) |

| Thermoregulation range | 1-399℃ | 1-399℃ | 1-399℃ |

| Continuous thermo printing speed | 20(Storks/min) | 22(Storks/min) | 25(Storks/min) |

| Volume of common foil-feeding | 1-800mm | 1-600mm | 1-500mm |

| Leapfrog frequency | 1-99 | 1-99 | 1-99 |

| Foil-feeding resolute | 1mm | 1mm | 1mm |

| Motor dates | 4(kw)/6(Series) | 4(kw)/4(Series) | 2.2(kw)/6(Series) |

| Overall Dimension | 1900×2000×1900mm | 1500×1700×1620mm | 1300×1300×1700mm |

| Net weight | 4700kg | 3100kg | 1800kg |