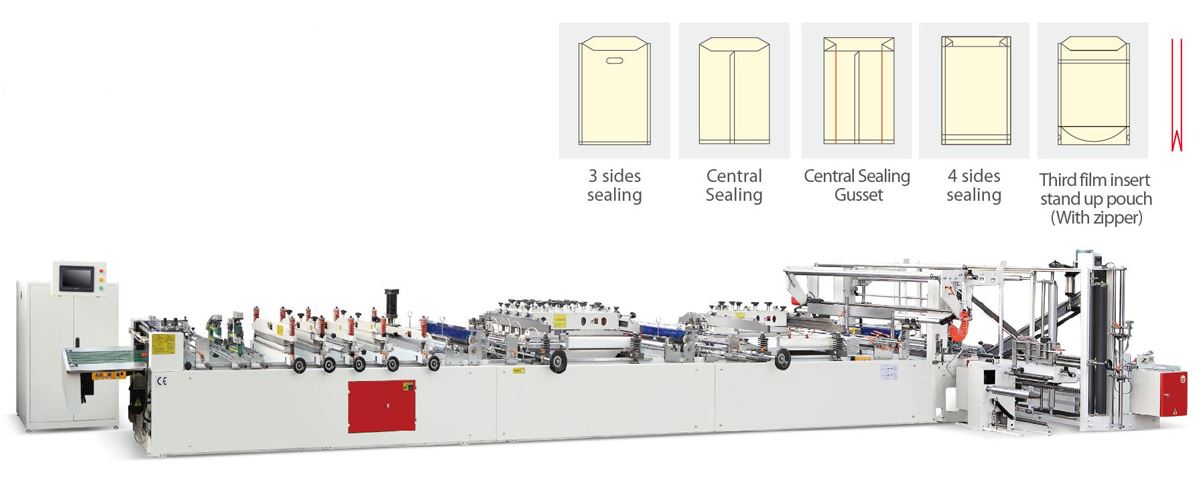

Heavy Duty Multifunctional Laminated Pouch Bag Making Machine, 600C+CS

This multifunctional laminated film pouch bag making machine is for making 3 side sealing, zipper bag , 4 side sealing bag, stand up pouch bag (doypack bag) and center sealing bag.

Features

- Main electric scheme: 4 servo motor for traction, with PLC used Panasonic from Japan., Touch Screen from Taiwan; main driving is alternating current with YASKAWA from JAPAN Transducer, automatic constant tension for unwinding.

- Thermal-sealing knife’s quantity of heat:

- Vertical-sealing adopts 5 groups for heating, cooling fluctuation from up and down;

- Vertical sealing adopt 1group for center sealing heating and zipper;

- Bottom sealing adopt 3 groups heating, 1 group for cooling .

- The type of control system: SSF-Ⅱ High speed laminating film bag making machine control system

Specification

| Speed of bag making | 40-140pcs/min |

| Line speed | ≤30 m/min (decided according the material) |

| Max width of bag | 580mm |

| Max height of bag | 380mm x Skip (the skip ≤6, which mean the max width size of bag is 380x6=2280mm ) |

| Dimension of roll material | ф600*1200mm (diameter* web-width) |

| Accuracy of orientation | ≤± 0.5mm |

| Quantity of temperature heating | 20 |

| Bound of temperature | 0-300 ℃ |

| Total power | 52kw |

| Overall dimension | (L*W*H) 12500×2450×1920mm |

| Weight of machine | 5900 kg |

| Color | white color of machines, red color for cover and door |

| Air compressor | 6HP |