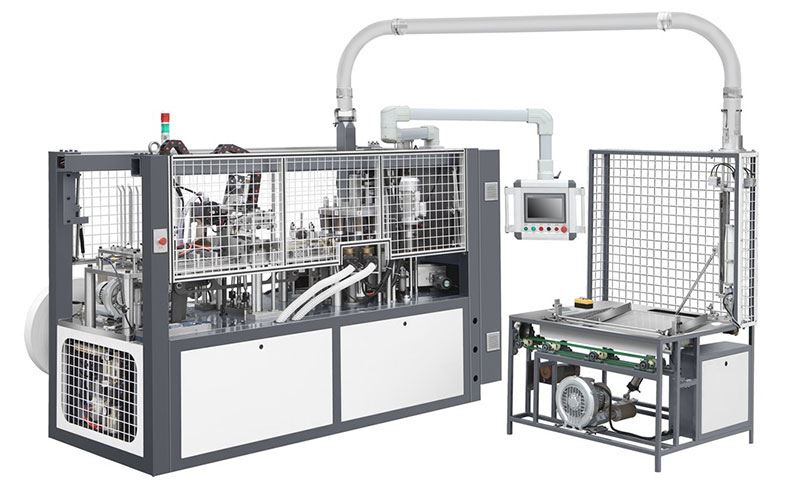

High Speed Paper Cup Forming Machine, JBZ-12H

This product has been discontinued and removed from our shelves.

JBZ-H High Speed Paper Cup Forming Machine is a high speed automatic machine with multi-working station.

It products single and double side PE paper cup through the procedure of automatic paper feeding, sealing, silicon oil lubrication, bottom punching, heating knurling, curling and cup can be of for beverage, ice cream etc.

This machine has adopted new technology, such as multi-working station rotary mould head, imported hot blowing equipment, and it is the first choice for the paper cup manufacturer.

Features

- with advance open type indexing cam structure, high precision making, insure the machine stable running.

- With imported non-flame heating system, reliability and improve the productivity.

- Encircling type steel structure, compact and stable frame.

- All the parts and components are standardized production, easy for machine maintenance.

- Adopt automatic closed lubrication system ensure the machine long period non-stop working at high speed.

- Intelligent design, PLC automatic control, with servo motor drive, automatic defective alarming, counting, and stop, etc.

Specification

| Cup size | 6~12oz (to out diameter:∮60mm~∮110mm, bottom: ∮50mm~∮70mm, height: 50~135mm, depth of bottom: 5~10mm ) |

| Rated speed | 90-110pcs/min |

| Main motor power | 2.2kw |

| Electro thermal power | 8.6/13.2kw |

| Actual power consumption | 7.5kw |

| Air source | 0.8 m3/min :0.6Mpa |

| Applicable base paper | 190~350g/ m2(single or double PE coating paper ) |

| Weight | 3500kg |

| Packing dimension | 740x400x1700mm and 1150x650x2000mm |

| Remark | Paper thickness error margin is ±0.05mm for the same set of mould |

| Oil spindle lubrication system and integrated steel structure frame |