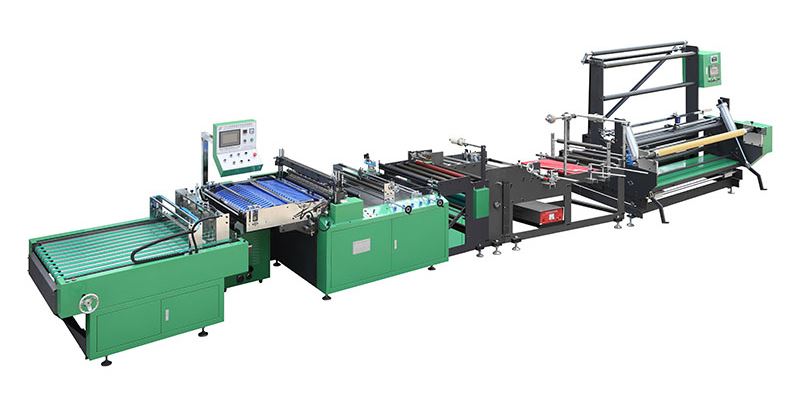

High Speed Heat Cutting Side Sealing Bag Making Machine, DRQ-C700

This High speed side sealing bag making machine is suitable for various kind of material such as BOPP, CPP, LDPE, HDPE, POF & laminated film,etc, which with printed or without printed. It is a kind of ideal equipment for making Stationery bag, ornaments bag, garment Bag, food bag and hang bag.

Features

- Touch screen operation, English and Chinese interface

- Two sets of imported servo motors constant tension feeding, arbitrary fixed length, accurate and stable photocell tracking.

- Imported photocell for color register, accurate size, stopping automatically when the label lost.

- Auto-sync adhesive tape attaching, pneumatic hole punching.

- Special alloy sealing knife, heat sealing perforation line, automatic constant temperature, firm and smooth sealing.

- Auto bag stacking conveyor, with vibration plate and pneumatic grippers assisted conveying.

- Unwind with air shaft and pneumatic material lifting, auto constant tension control, simulation web-guider with Italian Photocell, smooth and accurate feeding.

- Equipped with Ultrasonic device, Second folding device, Bottom gusset, Pearlized Film inserting device, Pneumatic hole puncher and Adhesive tape attaching device.

Specification

| Model | DRQ-C700 |

| Max. Unwinding Diameter | 550mm |

| Max. Film Unwinding Width | 1350mm |

| Bag Making Length | 70-650mm |

| Bag Sealing Width | 650mm |

| Max.Speed | 250pcs/min |

| Total power | 6KW |

| Power Supply | 380V/50HZ |

| Weight | 3000kg |

| Overall Dimensions(L*W*H) | 8800mm* 2200mm *1500mm |