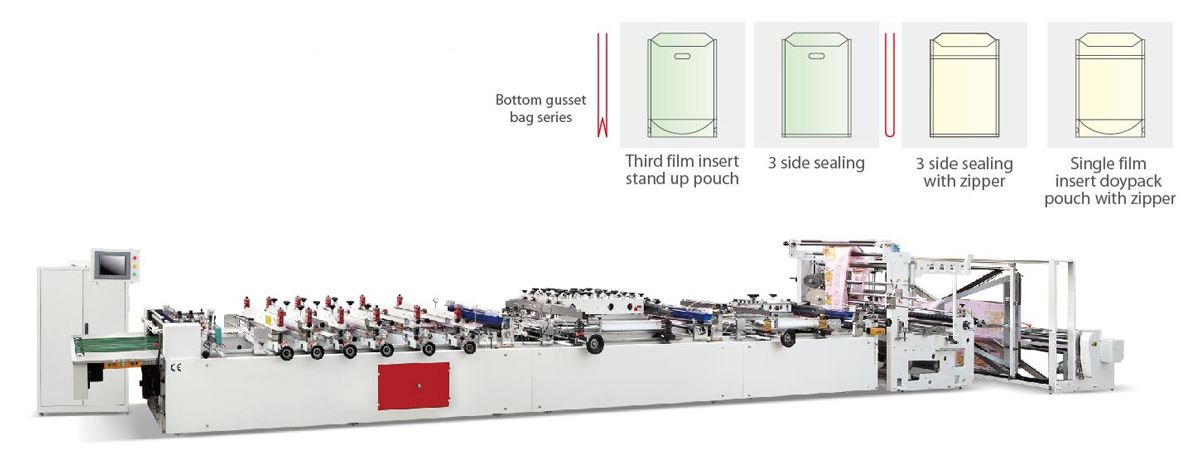

Pouch Bag Making Machine, 600C+FD

This pouch bag making machine can do for three side sealing, zipper bag, stand up bag (single sheet film folded material and normal stand up bag with another small piece film gusset ).

Features

- Three servo motor for traction from JAPA

- PLC adopts Panasonic from Japan; Touch Screen from Taiwan

- Main driving is alternating current with Yaskawa from JAPAN inverter, automatic constant tension for unwinding.

- Thermal-sealing knife’s quantity of heat:

- Vertical-sealing for zipper adopts 1 group for heating fluctuation,

- Vertical-sealing for side sealing adopt 5groups for heating fluctuation, cooling fluctuation from up and down

- Zipper flattening adopt 2 groups heating.

- Bottom sealing adopts 3 group heating, 1 group for cooling

Specification

| Max length of bag making | 380mm |

| Max width of bag making | 580mm |

| Dimension of roll material | Ф600*1200mm (diameter* web-width) |

| Accuracy of orientation | ≤± 0.5mm |

| Speed of machine | 150 hypo-minute |

| Speed of feeding | ≤35 m/min (according to the material) |

| Quantity of temperature heating | 22 |

| Bound of temperature | 0-300 ℃ |

| Total power | 45kw |

| Machine dimension | (L*W*H) 12300×2050×2000mm |

| Wight | About 4500kg |

| Color | White color of frame + red door |

| Type of control system | SSF-2 high speed laminating film bag making machine control system |

| Solid state relay | 22pcs |